Heating observation measuring device

MICROView

REFLOW + MICROSCOPE

Observation and measurement of heating change with image

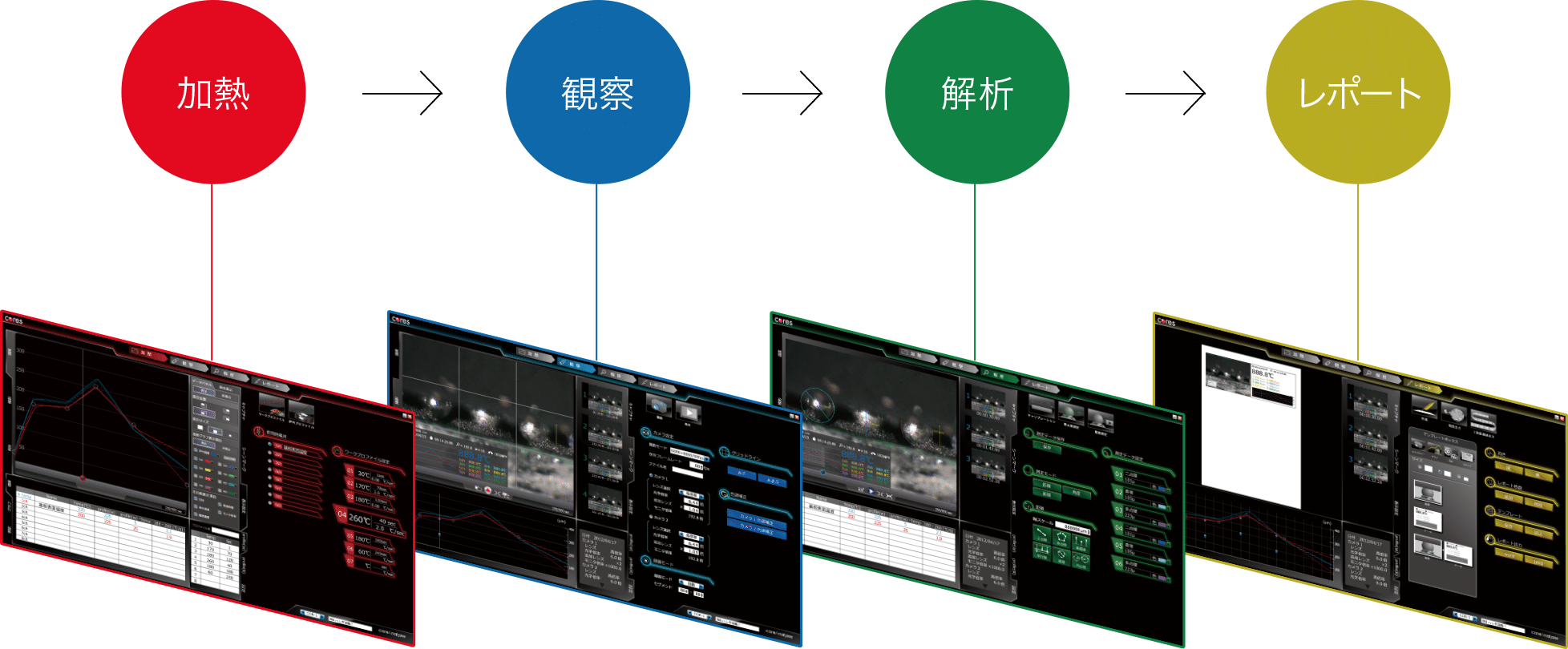

Heating, observation, measurement and report outputNecessary for analysisEverything is on this one.

In addition to conventional heating and observation, Microview implements measurement and reporting functions. This not only records the shape change during heating, it also makes it easy to quantify the behavior and output it to the report. We support the series of flow from “heating → observation → analysis → report” as “platform for mounting analysis” active in various production sites.

Phenomena in the reflow ovenSimulate on desk

In addition to conventional heating and observation, Microview implements measurement and reporting functions. This not only records the shape change during heating, it also makes it easy to quantify the behavior and output it to the report. We support the series of flow from “heating → observation → analysis → report” as “platform for mounting analysis” active in various production sites.

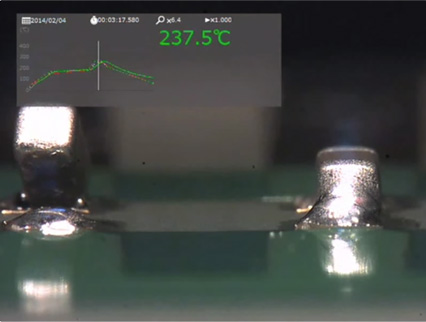

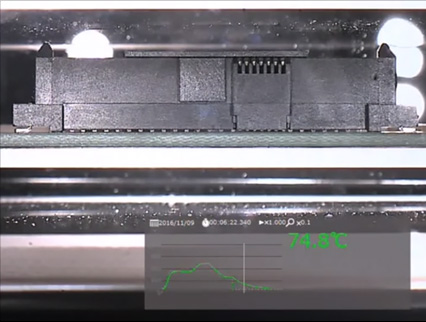

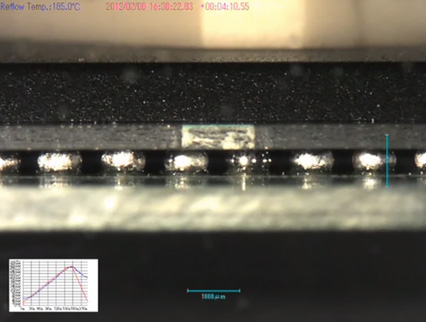

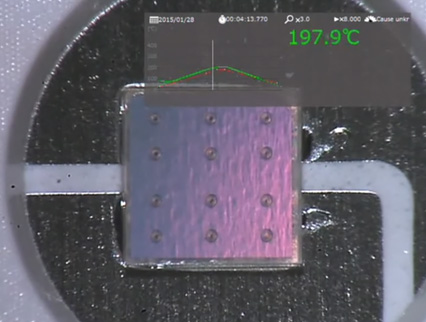

You can verify the state during heating in real time.

Consolidate implementation analysis on one stop.It greatly shortens the time for defect improvement.

At Microview, we have a software “coreAnalyser” that aggregates the mounting analysis that we had been doing with multiple devices, such as reflow oven, microscope and measuring microscope. Running on one stop, shooting during heating, quantification of behavior, and report output. It greatly improves the time for implementation analysis. Moreover, it can be used easily by anyone with an intuitive operation feeling.

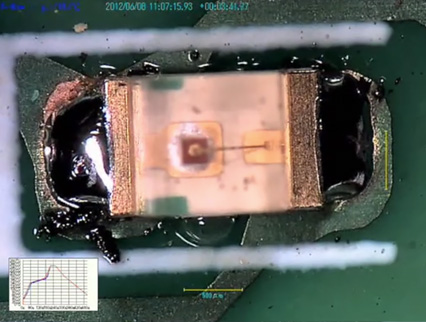

High magnificationDedicated digital microscope byClear picture

Microview’s digital microscope can observe at a high magnification of up to 339 times (when the maximum size of the software screen is set), and can observe very small samples. It can also be used as a normal digital microscope by removing the heating unit.

Minimal samples can also be clearly observed

Actual by convection heatingReproduce reflow environment

MICROView uses a convection heating method. Convection heating with hot air is close to the reflow environment during SMT, enabling more accurate analysis

Image of convection heating method. You can see how hot air is fed into the reflow

Easy to handleEasy installation

Microview which thoroughly used ease was stuck to the ease of installation. Space saving design that can be installed on a table. It operates with normal 100 V power supply. Large scale construction is not required at the time of introduction. Moreover, anyone can handle intuitive operation method on the touch panel immediately.

- Space saving design that can be installed on desktop

- Intuitive operation with touch panel

- Can be used as microscope

Measurement example

Microview has various applications tailored to the subject, you can choose according to the application. Here are some examples of measurement. Please refer to when considering.

Product lineup

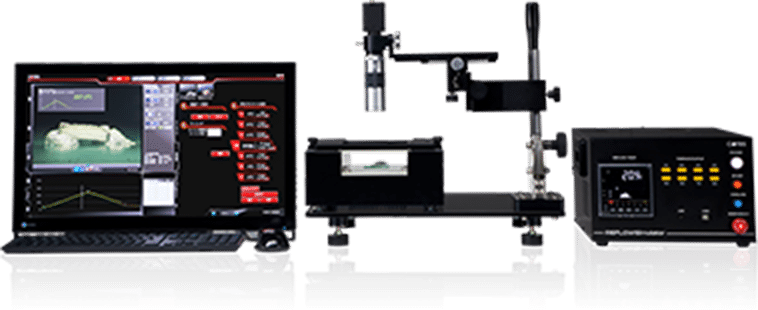

core9046a

Sample installation size Standard type with 50 x 50 mm

Sample installation size: (W) 52mm x (D) 52mm x (H) 25mm Temperature range: 400 ° C

MICROView series-core9046a catalog Language: Japanese

core9046a-100

Expanding the heating furnace, it corresponds to large parts such as automotive and small boards

Sample installation size: (W) 102mm × (D) 102mm × (H) 30mm Temperature range: 400 ℃

MICROView series-core9046a catalog Language: Japanese

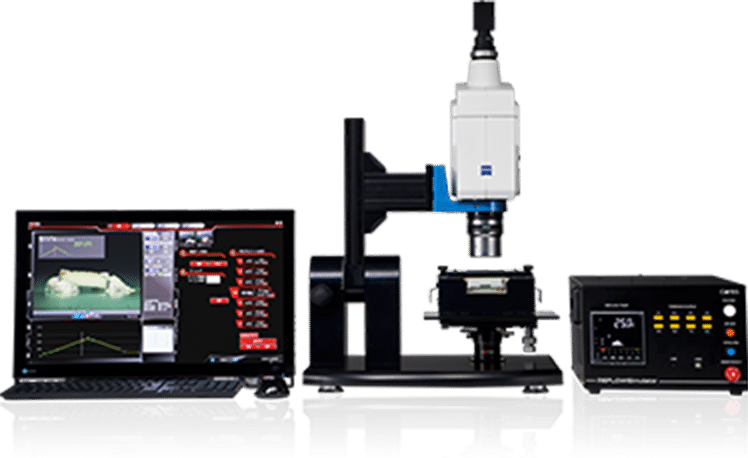

core9046a-z

ZEISS made lenses are mounted, minimal parts andUltra high magnification type suitable for material analysis

Sample installation size: (W) 52mm x (D) 52mm x (H) 25mm Temperature range: 400 ° C

MICROView series-core9046a catalog Language: Japanese

core9056a

Large type corresponding to A4 size sample

Sample installation size: (W) 210mm x (D) 300mm x (H) 40mm Temperature range: 300 ° C

MICROView series-core9046a catalog Language: Japanese

[EXP LAB]

You can experience the operability and possibilities with your own hands.

EXP LAB(CORES EXPERIENCE LAB TOKYO)is a laboratory and showroom where you can experience Cores products.

We have designed the space as a place where you can experience the product concept and operability, as well as the possibilities of advanced measuring instruments.

Please visit us when you are considering our products.

Inquiry by telephone

You can also make reservations and inquiries by telephone.

Reception: Weekday AM 10: 00 to 5: 00

Contact by e-mail here

フォームが表示されるまでしばらくお待ち下さい。

恐れ入りますが、しばらくお待ちいただいてもフォームが表示されない場合は、こちらまでお問い合わせください。